-

Product DescriptionCompany Info.<>

- Model:

- MT

- Applicable object:

- Products with aluminum foil inside the lid

- Types:

- testing equipment

- detection mode:

- infrared thermal imaging

- Suitable for industry:

- Pharmaceutical, chemical, food, etc.

- goods time:

- 2-4 weeks

- made in:

- Jinan

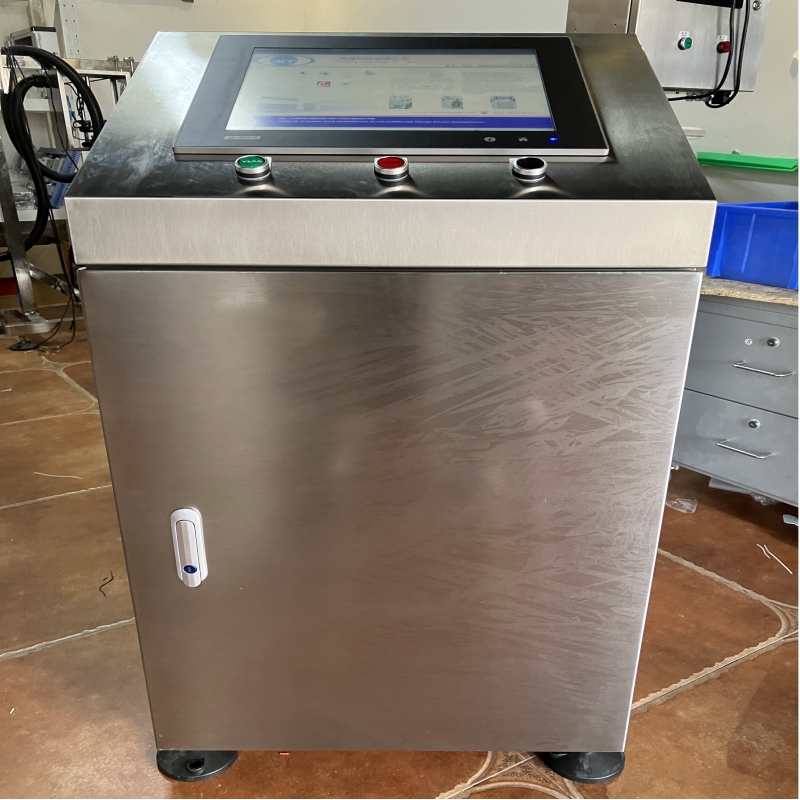

Lid aluminum foil sealing quality inspection equipment Infrared thermal imaging inspection equipment can be adapted to the original production line

Aluminum foil seal quality inspection machine is suitable for PP/PE bottle production line of medicine, food, lubricating oil, pesticide and other industries.

The detector adopts thermal imaging technology, combined withself-developedartificial intelligence algorithm, integrates identification, detection, calculation and self-judgment, and can stably identifythe quality defects of aluminum foil seals in PP/PE bottle production lines. Such as aluminum foil damage, aluminum foil false seal, aluminum foil reverse loading, no aluminum foil, no cover and other defects, the detector can quickly identify and make judgments. While effectively improving the packaging quality of the bottling production line, it can also improve the artificial intelligence level of the packaging production line.

Infrared thermalimagingaluminum foil seal quality inspection machine is an accurate quality inspection equipment, can achieve non-contact inspection of aluminum foil seal. The traditional seal quality inspection often needs contact inspection methods, which may cause damage or pollution to the product. By measuring the heat distribution in the sealing area, the infrared thermal imager can accurately detect the quality of the seal without touching the aluminum foil surface. By collecting and processing thermal image data at high speed, the temperature change and heat distribution in the sealing process can be captured in time. This allows operators to monitor seal quality in real time and adjust production parameters in time to ensure seal integrity and consistency.- Name(chinese)

- Name(English)

- Jinan Maotong Testing Equipment Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Jinan, Shandong, China

- Nearby port

- Tianjin,Qingdao,Shanghai

Jinan Maotong Testing Equipment Co., Ltd. is a national-level high-tech enterprise integrating research and development, manufacturing and sales of automated online testing equipment; It is mainly used in food, brewing, beverage, beverage, tobacco and other industries. It has accumulated a lot of experience in the process of enterprise cooperation and gradually formed industry-specific testing software. Through debugging and continuous improvement on the production line, functions have been further integrated to form a testing system equipment integrating machine testing software, automated control, and man-machine interface.- Name(chinese)

- Name(English)

- Jinan Maotong Testing Equipment Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Jinan, Shandong, China

- Nearby port

- Tianjin,Qingdao,Shanghai

Jinan Maotong Testing Equipment Co., Ltd. is a national-level high-tech enterprise integrating research and development, manufacturing and sales of automated online testing equipment; It is mainly used in food, brewing, beverage, beverage, tobacco and other industries. It has accumulated a lot of experience in the process of enterprise cooperation and gradually formed industry-specific testing software. Through debugging and continuous improvement on the production line, functions have been further integrated to form a testing system equipment integrating machine testing software, automated control, and man-machine interface. -

Send your message to this supplier*From:*To:

Mr. Jack

*Message:

Mr. Jack

*Message:Inquiry

Copyright © 2003 - 2026 Goepe.com All rights reserved.